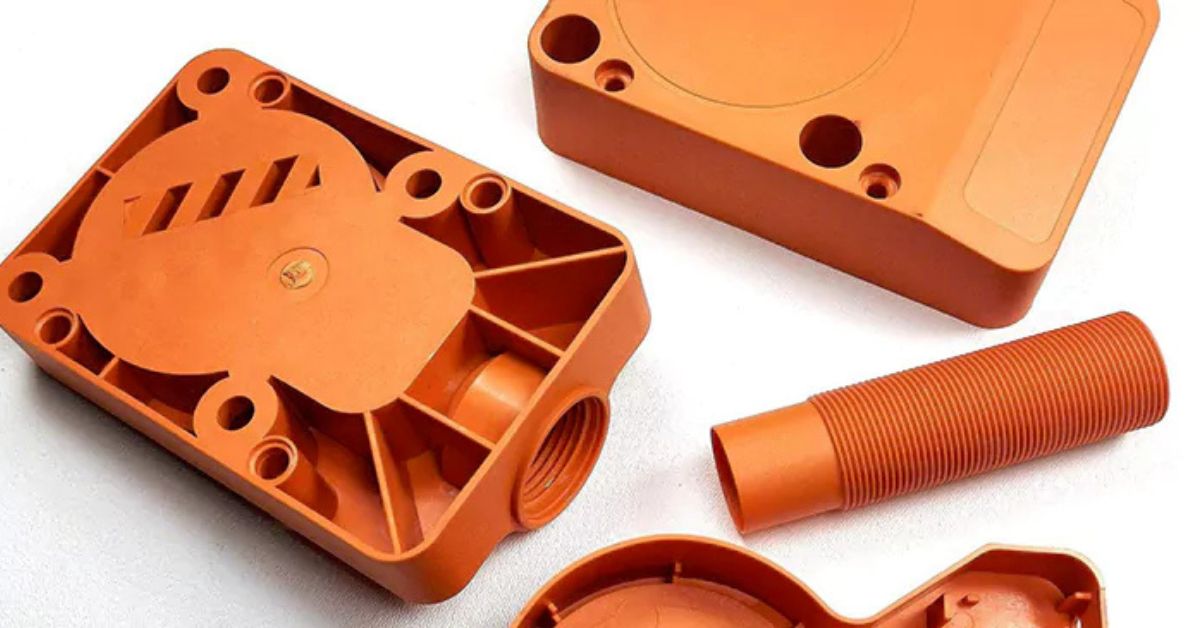

Precision Solutions for Large-Scale Plastic Components

Meta Description: Discover the challenges and innovative solutions for producing large plastic parts with high precision, from material selection to advanced molding techniques.

Manufacturing large plastic components presents a unique set of challenges that go far beyond simply scaling up smaller designs. As parts increase in size, so do the risks of defects like warping, inconsistent wall thickness, and surface blemishes. For industries where precision is non-negotiable—such as automotive, aerospace, and industrial equipment—these challenges can significantly impact product performance, safety, and cost.

Successfully producing large-scale plastic components requires a deep understanding of materials, advanced molding processes, and meticulous quality control. It’s about achieving tight tolerances and flawless finishes on a grand scale. This post explores the key considerations and innovative solutions that enable manufacturers to overcome these hurdles and deliver high-quality, large plastic parts consistently. We will cover everything from material selection and mold design to the latest advancements in processing technology.

The Unique Challenges of Large-Part Molding

Creating large plastic components is not just about using a bigger machine. The physics of plastic processing change significantly as the volume of material and the surface area of the part increase. Understanding these challenges is the first step toward finding effective solutions.

Material Selection and Management

The choice of raw material is critical. For large parts, the plastic must not only meet the final product’s performance requirements (like strength, chemical resistance, or UV stability) but also behave predictably during the molding process. Polymers with high shrinkage rates can be particularly problematic, leading to dimensional instability and warping as the part cools. Furthermore, managing large volumes of raw material, ensuring it is properly dried and consistently fed into the machine, is a logistical challenge in itself.

Mold Design and Engineering

The mold is the heart of the injection molding process, and for large parts, its design is incredibly complex. Molds for components like car bumpers or industrial containers can weigh several tons and must be engineered to withstand immense pressure. Key considerations include:

● Gating Strategy: Deciding where and how the molten plastic enters the mold cavity is crucial for ensuring even filling and minimizing stress.

● Cooling Channels: An effective cooling system is vital for controlling the cooling rate across the large surface area of the part. Uneven cooling is a primary cause of warping and sink marks.

● Venting: Air trapped inside the mold cavity can prevent the plastic from filling completely, causing defects. Proper venting allows this air to escape.

Processing and Cycle Times

Large parts require longer cycle times. It takes more time to inject the large volume of plastic, and significantly more time for the part to cool sufficiently before it can be ejected from the mold. Optimizing these cycle times without compromising part quality is a constant balancing act. Long cycles can increase production costs, while rushing the process can lead to a higher scrap rate.

Innovative Solutions for Precision at Scale

Fortunately, advancements in technology and processing techniques provide powerful solutions to these challenges. By combining the right tools with expert knowledge, manufacturers can achieve exceptional precision in large-scale components.

Advanced Material Formulations

Polymer science has led to the development of materials specifically engineered for large-part molding. These include low-shrink resins and filled materials (using glass fiber or minerals) that enhance dimensional stability and mechanical strength. These advanced polymers help counteract the natural tendency of large parts to warp or distort during cooling.

Sophisticated Mold-Flow Simulation

Before any steel is cut for the mold, engineers can use mold-flow simulation software to predict how the plastic will behave. This powerful tool allows them to:

● Visualize the filling pattern of the molten plastic.

● Identify potential problem areas like weld lines or air traps.

● Optimize the placement of gates and cooling channels.

● Predict cycle times and shrinkage rates.

By simulating the entire process digitally, manufacturers can refine the mold design and processing parameters, saving significant time and money by avoiding costly physical trials and errors.

Advanced Molding Techniques

The process of heavy injection molding is continually evolving. Modern machines offer greater control and precision than ever before. Techniques like gas-assist and structural foam molding are particularly beneficial for large parts.

● Gas-Assist Molding: In this process, pressurized nitrogen gas is injected into the mold after the plastic. The gas creates hollow channels within the part, which helps pack out thick sections, reduce sink marks, and lower the overall part weight without sacrificing strength.

● Structural Foam Molding: This low-pressure process introduces a blowing agent into the plastic, creating a part with a cellular core and a solid outer skin. The resulting components are strong, lightweight, and dimensionally stable, making this an excellent choice for large structural panels.

Robotics and Automation

Automation plays a key role in ensuring consistency and quality. Robots are used for part removal, which ensures that large, still-warm parts are handled gently and uniformly, reducing the risk of distortion. Automated systems can also perform secondary operations like trimming, assembly, and quality inspection with a high degree of repeatability.

Your Partner in Precision Manufacturing

Achieving precision in large-scale plastic components requires a combination of engineering expertise, advanced technology, and a commitment to quality. From initial design consultation and material selection to sophisticated molding and post-production finishing, a holistic approach is essential for success. By leveraging cutting-edge solutions like mold-flow simulation and advanced molding techniques, it is possible to produce large, complex parts that meet the most demanding specifications.

If your project demands high-quality, large-scale plastic components, partnering with an experienced manufacturer can make all the difference. Explore how tailored precision solutions can bring your most ambitious designs to life while ensuring performance and reliability.

Also Read: Livermores Bexley: An In‑Depth Look